Description

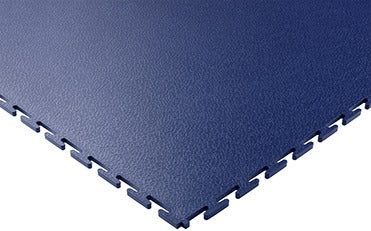

7mm PVC Interlocking Garage Floor Tiles

Technical Specifications

Performance Characteristics

Why 7mm Thickness is Critical

The 7mm profile represents the engineering sweet spot for interlocking PVC garage floor tiles. It provides 67% greater structural rigidity than 5mm alternatives, superior load distribution across point loads, and better spanning capability over substrate imperfections—without the cost premium of 10mm+ industrial systems.

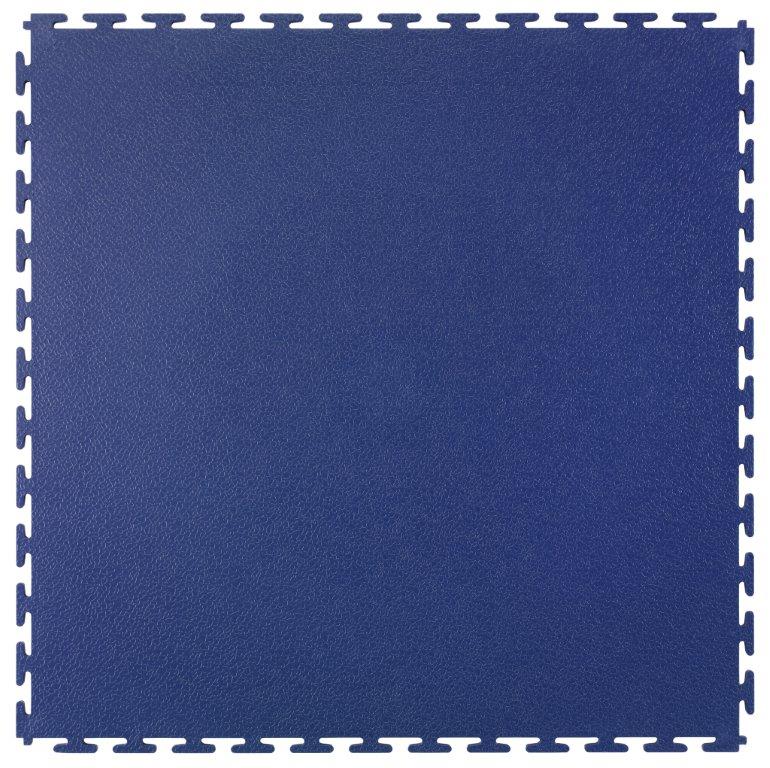

Surface Pattern Selection

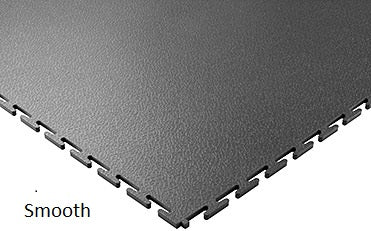

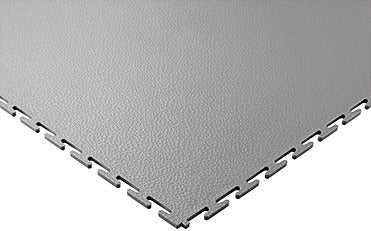

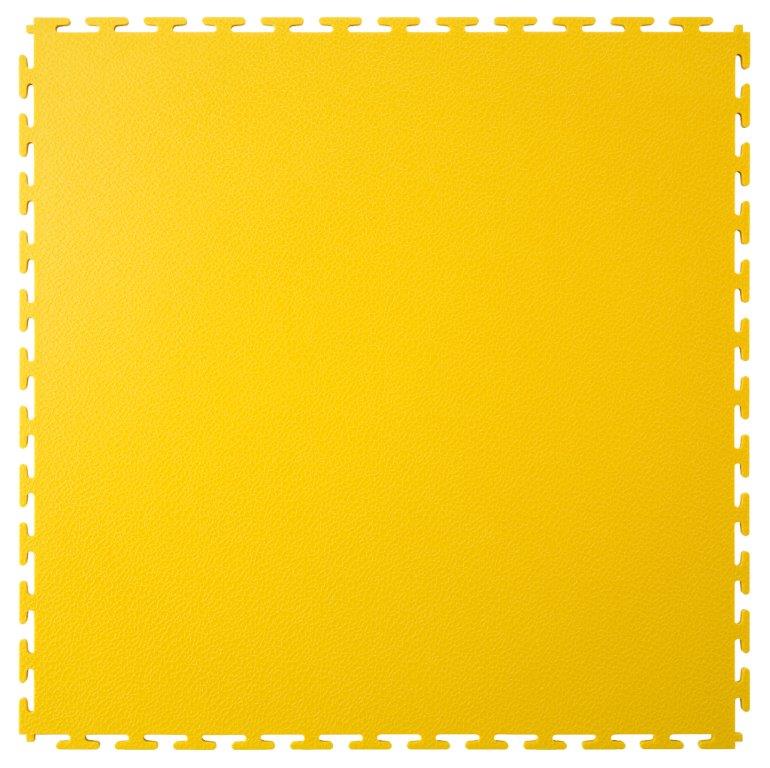

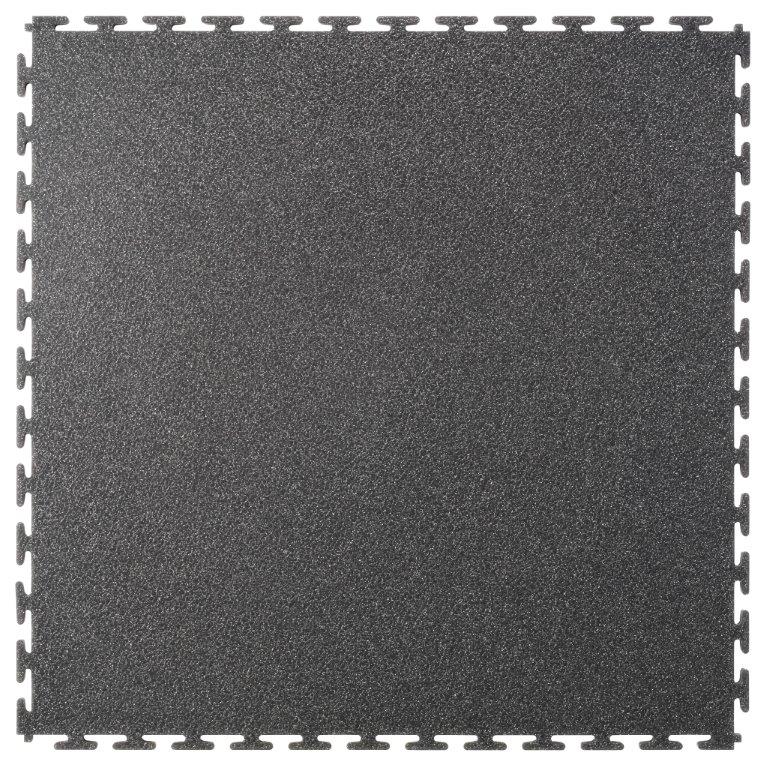

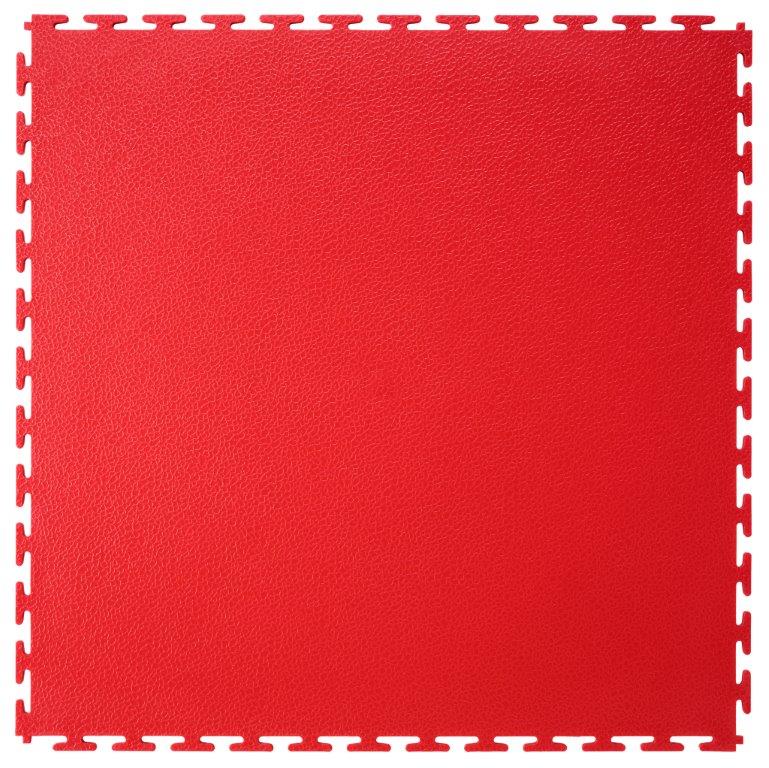

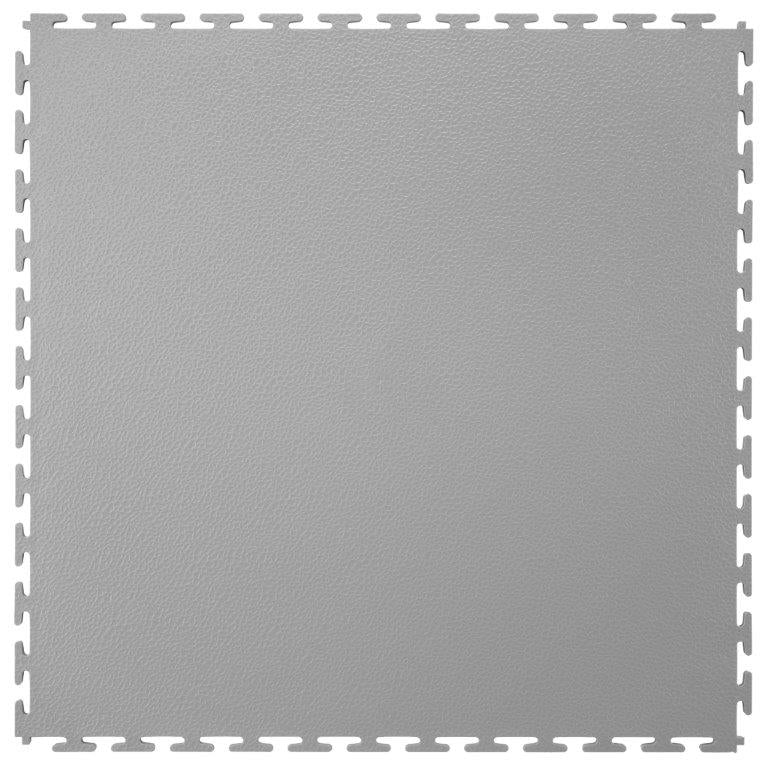

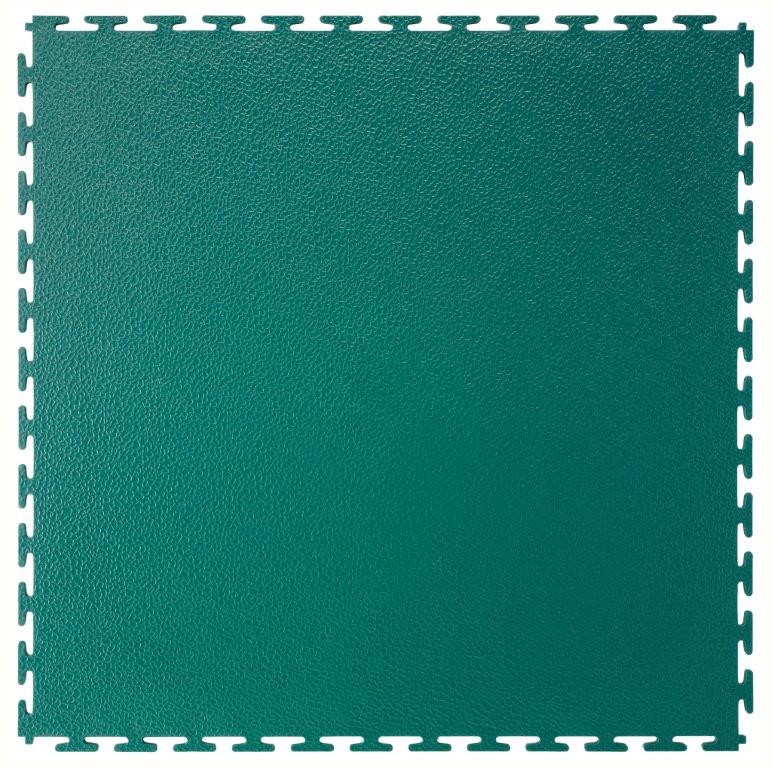

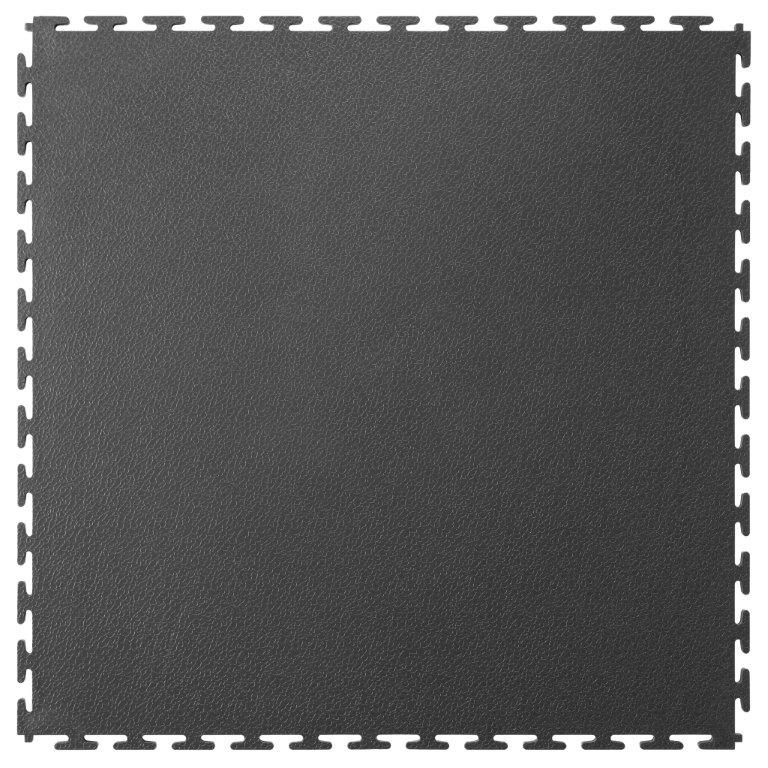

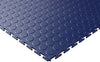

Smooth Finish

- Sleek, professional appearance with high-gloss finish ideal for vehicle showrooms

- Easy cleaning – sweep or damp mop in seconds with no debris accumulation

- R10 slip resistance certified for dry conditions and clean workshops

- Optimal for rolling equipment, trolley jacks, and wheeled tool cabinets

- Perfect for classic car storage and display areas

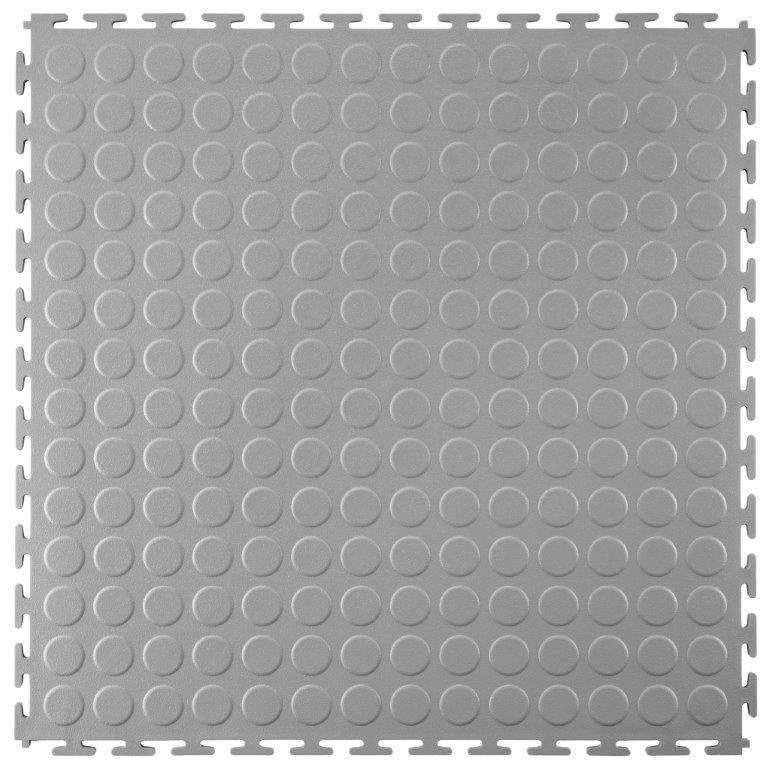

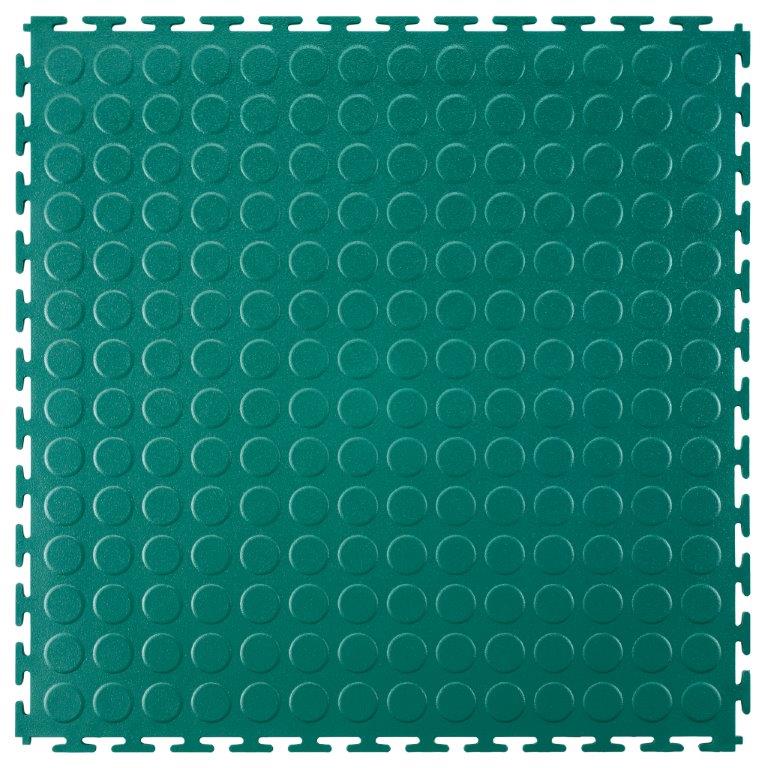

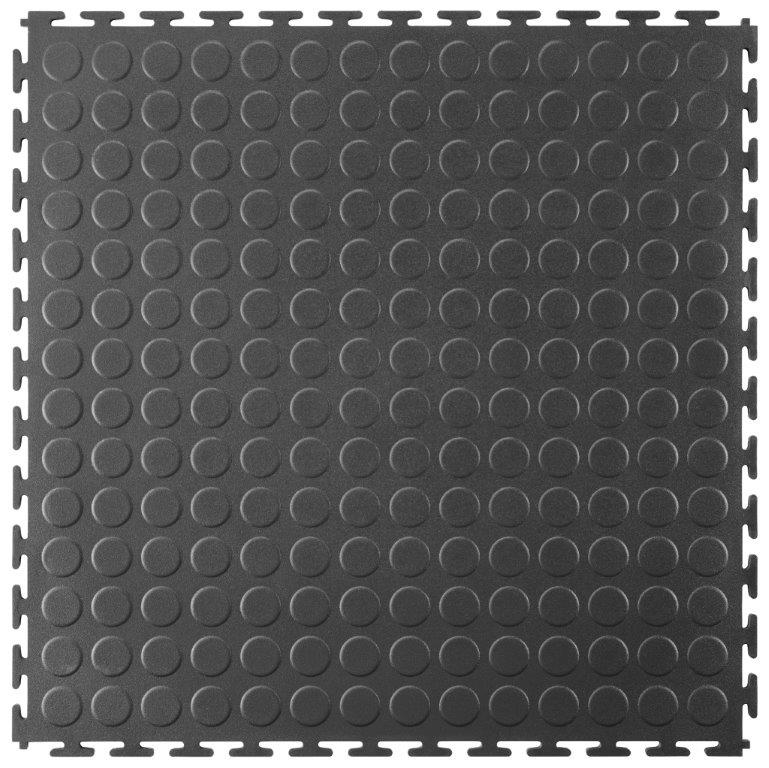

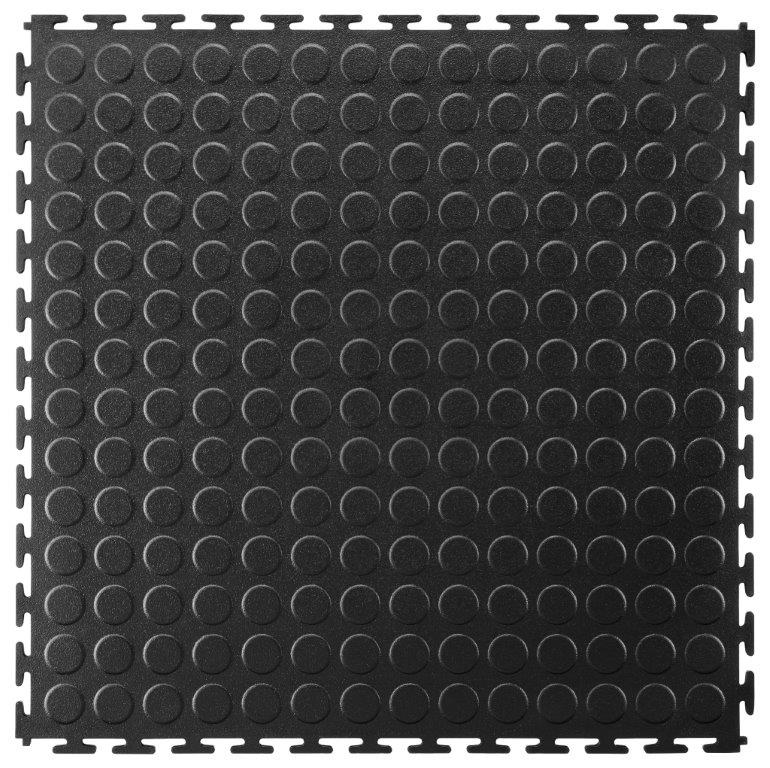

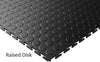

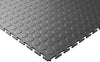

Raised Disk Pattern

- R11 slip resistance certified for wet and oily working conditions

- Circular studs create air gaps for drainage and debris clearance

- Enhanced grip for safe working in automotive maintenance bays

- Hides minor scratches and wear patterns better than smooth finish

- Recommended for mechanical workshops and high-traffic industrial zones

Ideal Applications

Installation Guide

- Prepare Surface: Sweep and clean substrate thoroughly. Remove all oil, grease, and loose debris. Substrate must be dry with moisture content below 4%.

- Plan Layout: Start from one corner, working across the room. No expansion gaps required for areas under 100m². Calculate tile requirements at 4 tiles per m² plus 10% overage.

- Click Tiles Together: Align dovetail edges at 45° angle and press down firmly until locked. The hidden interlock system requires no adhesive or special tools.

- Cut Perimeter Tiles: Use sharp utility knife and straight edge for straight cuts. For curves and complex shapes, use jigsaw with fine-tooth blade.

- Complete Installation: Walk over completed floor to ensure all connections are fully seated. Individual tiles can be lifted for future substrate access.

Installation Efficiency

Average installation rate: 50-75m² per hour with a single installer. Typical single-car garage (18m²) installs in under 30 minutes. No professional contractor required.

Performance Comparison

| Specification | 5mm Tiles | 7mm Tiles (Ours) | 10mm+ Industrial |

|---|---|---|---|

| Structural Rigidity | Moderate (edge curl) | Excellent (67% stronger) | Maximum |

| Load Capacity | 15 tonnes/m² | 25 tonnes/m² | 40+ tonnes/m² |

| Installation Ease | Easy | Easy (DIY-friendly) | Moderate (heavier) |

| Cost Effectiveness | Budget | Optimal Balance | Premium |

| Substrate Tolerance | ±2mm/3m | ±3mm/3m | ±5mm/3m |

| Expected Lifespan | 8-12 years | 15-20 years | 20+ years |

Maintenance & Longevity

Daily Maintenance

- Sweep or vacuum to remove loose debris and workshop dust

- Damp mop with neutral pH cleaner for routine cleaning

- Wipe oil spills immediately with absorbent cloth to prevent tracking

Deep Cleaning

- Citrus-based degreaser for stubborn automotive stains and buildup

- Pressure wash (max 1500 PSI) for heavy soiling in industrial environments

- Isopropyl alcohol removes tire marks and scuff marks effectively

Expected Lifespan

- 15-20 years in residential garages with normal use

- 10-15 years in commercial workshops and automotive facilities

- 8-12 years in high-traffic industrial manufacturing environments

Frequently Asked Questions

Professional-Grade Flooring. Industrial-Strength Performance.

Transform your garage or workshop with the UK's premium 7mm PVC interlocking floor tiles. Engineered for durability, designed for professionals, priced for everyone.

Free UK Delivery · Expert Support